Service Troubleshooting Application - Turns 4-Hour Equipment Failures Into 15-Minute Self-Service Fixes

Save ₹2-5 Lakhs annually in reduced downtime. Join 200+ Indian manufacturers who resolved 85% of issues without waiting for R&D teams.

The Hidden Cost of Equipment Downtime

Real Scenario: Your ₹2 crore production line stops due to a sensor error. Service engineer identifies the issue but needs R&D approval for recalibration. R&D team is in meetings. Production waits 4 hours. Cost: ₹1,00,000 for a 15-minute fix.

Project Overview

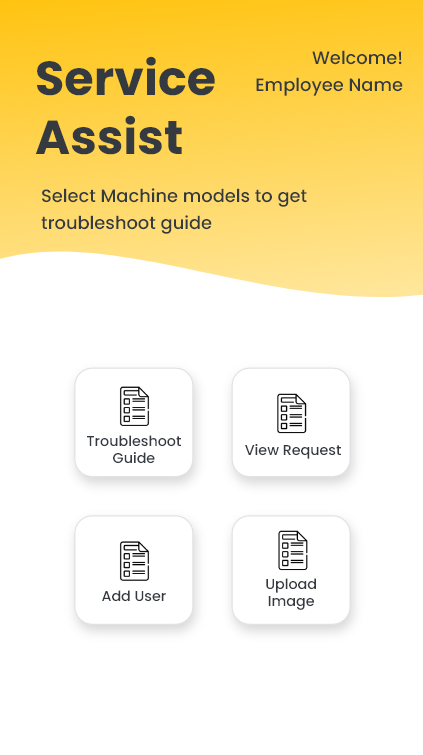

A web-based troubleshooting app that helps service engineers and operators quickly diagnose and resolve issues without relying on HO/R&D teams for every small problem.

Current Challenges

₹2-5 Lakh Annual Loss Per Machine

Every equipment breakdown costs ₹25,000-50,000 per hour in lost production. With 15-20 incidents annually, costs spiral to lakhs.

4-6 Hour Average Resolution Time

Service engineers wait for R&D approval even for simple sensor calibration or parameter adjustments, extending costly downtime.

60% of R&D Time Wasted on Routine Issues

₹10,000/day R&D engineers spend majority of time on repetitive troubleshooting instead of innovation and development work.

₹2-5 Lakh Annual Loss Per Machine

Every equipment breakdown costs ₹25,000-50,000 per hour in lost production. With 15-20 incidents annually, costs spiral to lakhs.

4-6 Hour Average Resolution Time

Service engineers wait for R&D approval even for simple sensor calibration or parameter adjustments, extending costly downtime.

₹2-5 Lakh Annual Loss Per Machine

Every equipment breakdown costs ₹25,000-50,000 per hour in lost production. With 15-20 incidents annually, costs spiral to lakhs.

4-6 Hour Average Resolution Time

Service engineers wait for R&D approval even for simple sensor calibration or parameter adjustments, extending costly downtime.

60% of R&D Time Wasted on Routine Issues

₹10,000/day R&D engineers spend majority of time on repetitive troubleshooting instead of innovation and development work.

Transform Downtime Into Uptime

Self-service troubleshooting that pays for itself within 3 months

ROI Breakdown for Typical Indian Manufacturer

Before vs After Implementation

BEFORE - Traditional Process

AFTER - Self-Service Process

Key Features

User Login System

Secure authentication system for different user roles and access levels.

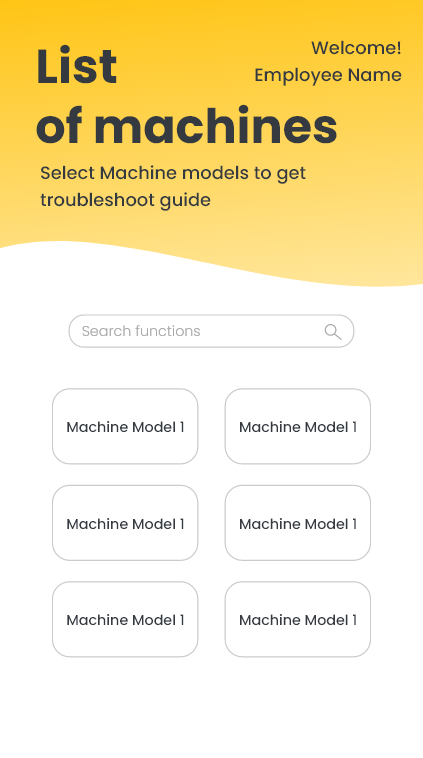

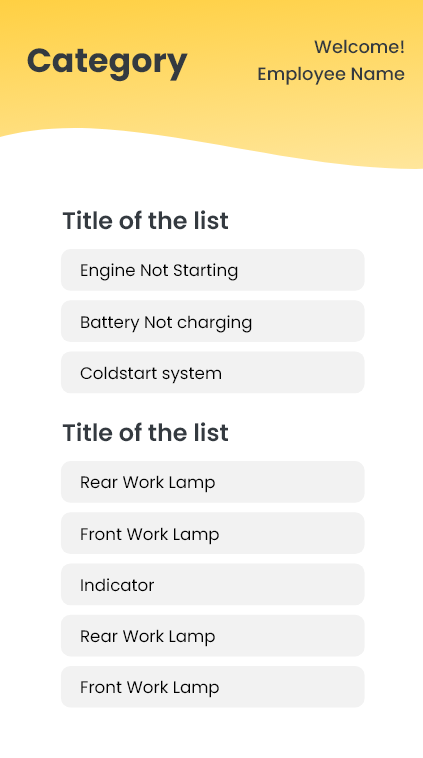

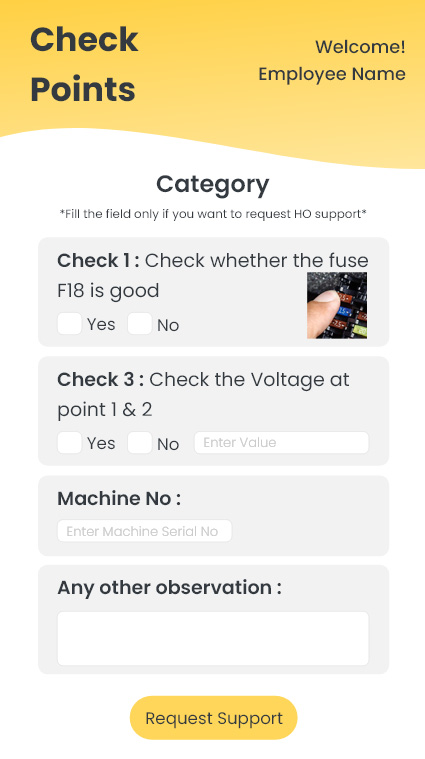

Machine Model & Function-based Troubleshooting

Intelligent system that guides users through troubleshooting based on specific machine models and functions.

Real-time Component Images

Visual aids with high-quality component images to assist in identification and troubleshooting.

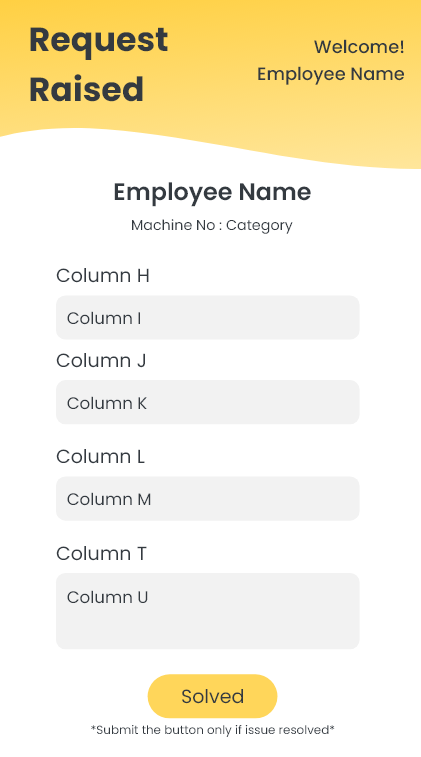

Request Submission with Observations

Easy-to-use form system for submitting unresolved issues with detailed observations.

Google Translate Integration

Multi-language support for global accessibility and ease of use.

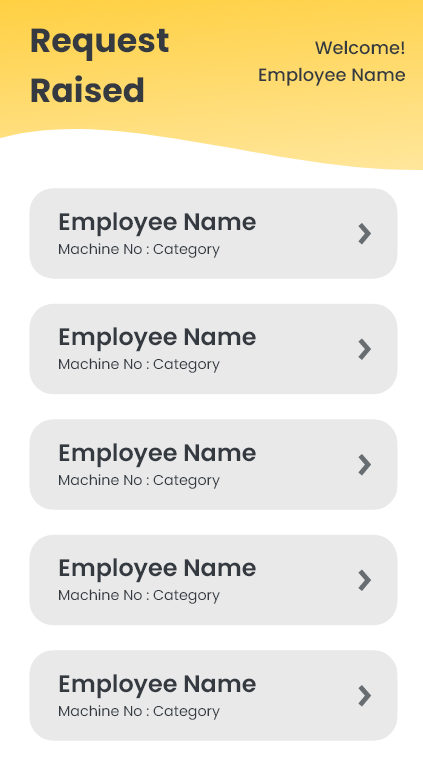

Progress Tracking

Track troubleshooting progress and maintain history of resolved issues.

User Login System

Secure authentication system for different user roles and access levels.

Machine Model & Function-based Troubleshooting

Intelligent system that guides users through troubleshooting based on specific machine models and functions.

Real-time Component Images

Visual aids with high-quality component images to assist in identification and troubleshooting.

Request Submission with Observations

Easy-to-use form system for submitting unresolved issues with detailed observations.

User Login System

Secure authentication system for different user roles and access levels.

Machine Model & Function-based Troubleshooting

Intelligent system that guides users through troubleshooting based on specific machine models and functions.

Real-time Component Images

Visual aids with high-quality component images to assist in identification and troubleshooting.

Request Submission with Observations

Easy-to-use form system for submitting unresolved issues with detailed observations.

Google Translate Integration

Multi-language support for global accessibility and ease of use.

Progress Tracking

Track troubleshooting progress and maintain history of resolved issues.

How It Was Built

Google Sheets → Database

Used Google Sheets as a lightweight database for storing troubleshooting checkpoints and data.

Google Apps Script → API

Created API endpoints using Google Apps Script to fetch data from the sheets database.

HTML, CSS, JavaScript → Web Application

Built the frontend using modern web technologies for optimal user experience.

ChatGPT + Domain Knowledge

Leveraged AI assistance combined with in-house domain expertise for development guidance.

Application Walkthrough

Advantages & Limitations

Advantages

Efficiency Improvement

Significantly reduces time spent on routine troubleshooting tasks.

Multi-language Accessibility

Google Translate integration enables global accessibility.

Scalable for Multiple Machines

Easily expandable to cover different machine models and types.

Guidance for Unresolved Issues

Structured approach to escalate complex issues to experts.

Limitations

Requires Internet

Application needs internet connectivity to function properly.

Limited API Requests on Free Tier

Google Sheets API has usage limits on the free tier.

Data Access Rights Management

Requires proper user access control and data security measures.

Device Compatibility

Optimized for desktop/laptop use, mobile experience may vary.

Customer Feedback & Ratings

"More helpful than expected, real-time usage will finalize ratings."

— Service Team Lead